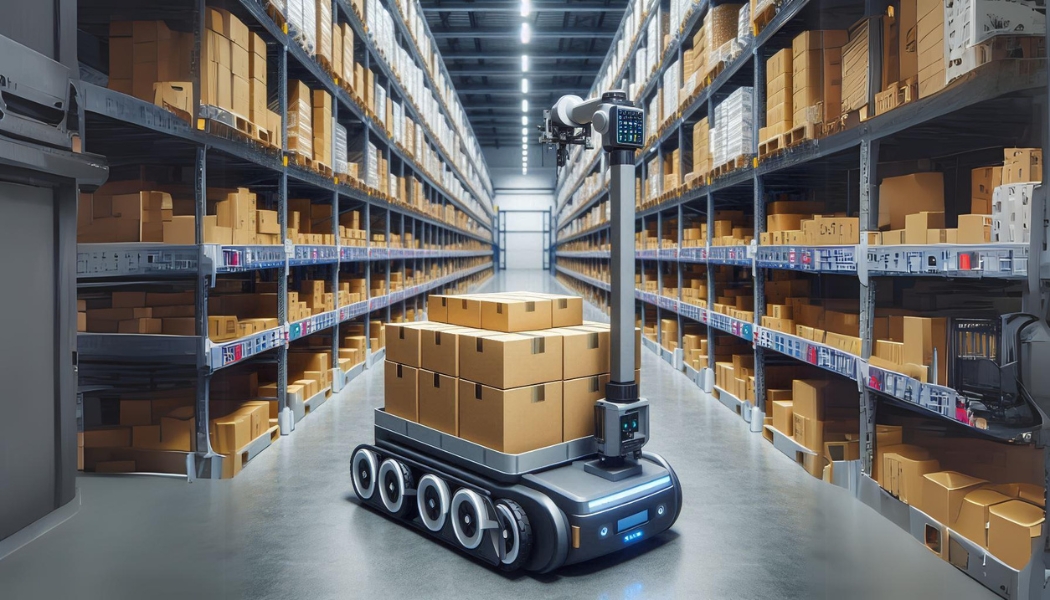

AGVs, quick for Automated Guided Autos, are autonomous cellular robots that navigate by means of pre-determined routes inside a office facility. These clever machines transfer items and supplies effectively with out human involvement. The know-how is being revolutionized with machine imaginative and prescient know-how, which helps the AGVs transfer by means of complicated environments, detect objects, and assist in making clever real-time selections.

By equipping the AGVs with machine imaginative and prescient programs, companies can optimize their warehousing processes, cut back human errors, and supply safer working circumstances. It’s not unreal to say that the adoption of those driverless autos with machine imaginative and prescient is not only a development however a necessity for corporations aiming to remain aggressive in a quickly evolving market.

On this article, we are going to discover:

- Idea of Automated Guided Autos (AGVs) and their function in fashionable warehousing

- Rationalization of AGVs, varieties, and key parts

- Affect of machine imaginative and prescient on AGV efficiency

- Advantages, real-world functions, and future traits in AGV know-how

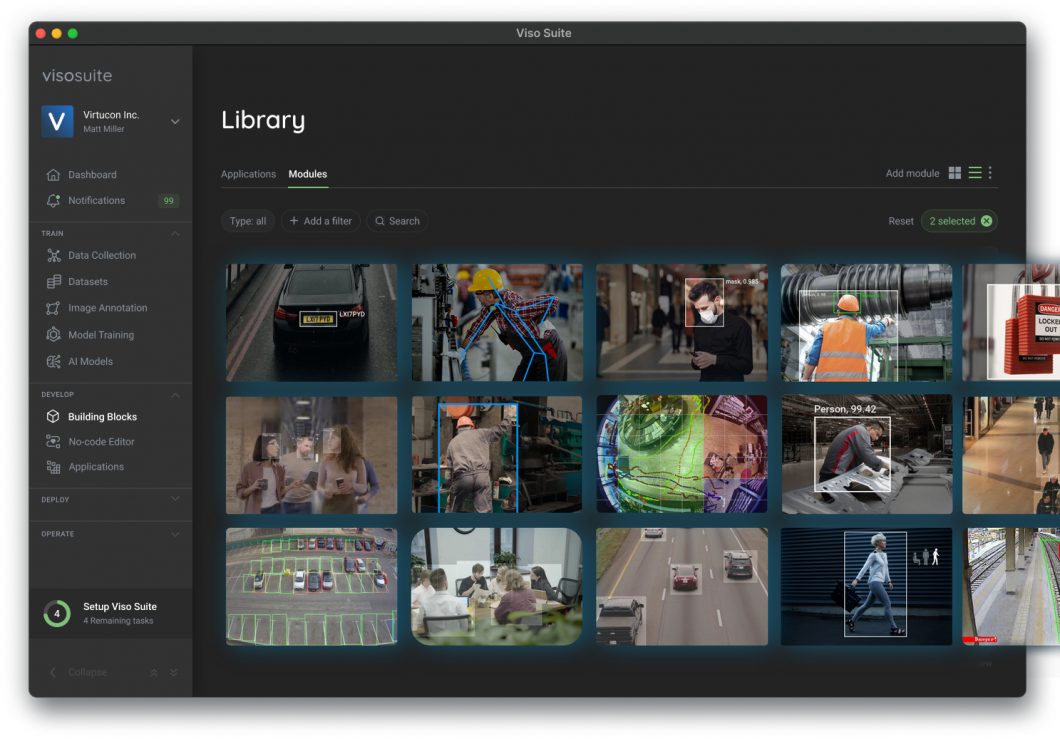

About us: Viso Suite is a versatile and scalable infrastructure developed for enterprises to combine laptop imaginative and prescient into their tech ecosystems seamlessly. Viso Suite permits enterprise ML groups to coach, deploy, handle, and safe laptop imaginative and prescient functions in a single interface. To study extra, ebook a demo with our group.

What are Automated Guided Autos?

Automated Guided Autos are driverless, mechanically managed autos designed to move supplies inside a producing facility, warehouse, or distribution heart. The car navigates by means of the set routes often outlined with wires, magnetic strips, or laser paths embedded within the flooring. An AGV follows set paths across the office, and a pc centrally controls its motion to make sure efficient and secure journey round a warehouse.

Whereas the idea of AGVs dates again to the Nineteen Fifties, speedy developments in synthetic intelligence, sensor know-how, and machine imaginative and prescient have propelled these programs into a brand new period. Immediately’s AGV is just not merely a preprogrammed machine operating alongside a set path; it’s a complicated, adaptive system able to interacting with its environment and attentive to all adjustments inside that surroundings.

Kinds of Automated Guided Autos (AGVs)

AGVs are available in varied varieties, every designed for particular duties:

Towing Autos

Towing AGVs are one of many oldest types of autonomous robots and proceed to be produced at present. These autos are designed to tug trailers and might deal with masses between 2,000 kilos and a formidable 160,000 kilos. It is usually referred to as “Tugger AGVs.”

They’re a safer different to manually working tuggers, particularly in transferring trailers or trains of trailers in a warehouse surroundings. Furthermore, these machines have the aptitude of hauling a number of trailers collectively, which will increase effectivity and security in materials dealing with operations.

Unit Load AGVs

Unit Load AGV is a specialised car with decks. They’re designed notably to deal with unit masses successfully. A few of its varieties embody carry and decrease decks, powered or non-powered curler decks, chain or belt decks, and customized decks with a number of compartments. Unit Load AGVs usually have an computerized load-transfer function, which makes them supreme for systematic material-handling environments that require very detailed transport and dealing with of supplies.

Mild Load AGVs

Mild Load AGVs are sometimes designed to move small elements, baskets, or different mild masses with capacities within the vary of roughly 500 kilos or much less. They discover functions in light-manufacturing environments the place smaller areas and transport of small, light-weight supplies are key necessities. For that reason, Mild Load AGVs are largely supreme for compact areas the place greater autos wouldn’t be needed.

Meeting Line AGVs

Meeting line AGVs are an upgraded type of lift-carry load AGVs for mild load appropriate for serial meeting traces. Such autos are helpful for transferring small elements from one course of level to a different on an meeting line that’s utilized in assembling merchandise. Meeting Line AGVs work nicely in areas with much less availability of areas comparable to the sunshine manufacturing environments. These compact autos make sure that elements are delivered to the proper place on the proper time.

Automated Guided Pallet Vans

Automated Guided Pallet Vans are designed to move palletized masses to and from flooring degree. This autonomous function eliminates the necessity for fixed-load stands. These AGVs streamline the motion of pallets inside a warehouse and cut back the necessity for guide load dealing with. Briefly, we are able to say their potential to deal with palletized masses immediately from the ground to the warehouse racks makes them a flexible software for contemporary warehousing operations.

Automated Guided Hybrid Autos

These autos mix all some great benefits of automated operation with the pliability of guide management. These are tailored from commonplace man-on-board vans and configured to carry out absolutely automated operations or to be manually pushed by a fork truck driver. This versatility makes them supreme for duties comparable to trailer loading and delivering supplies round warehouses. Whereas they’re mostly geared up with forks, they are often custom-made to deal with varied load varieties, providing a versatile resolution for various materials dealing with duties and desires.

Key Parts of AGVs

Automated Guided Autos have 4 fundamental parts: the controller, sensors, actuators, and energy system. Every element performs an important function within the AGV’s performance and efficiency. Let’s focus on them intimately.

Controller

The controller operates because the mind for the AGV. It accepts data from sensors, processes it for decision-making, and instructions the AGV operations. Its necessary elements embody:

- Microprocessor: A high-level laptop chip that interprets software program and algorithms which can be a part of the AGV.

- Reminiscence: The place it retains maps, directions, and operational information.

- Communication module: An interface that enables the controller to work together with a central management system or different AGVs.

- Software program: This contains navigation algorithms, process scheduling, and security protocols.

The controller interprets sensor information, plans the routes, and sends out the instructions to actuators. On the identical time, it additionally offers with the full-scale operation administration issues of the AGV, comparable to battery administration and error dealing with.

Sensors

Sensors act because the eyes and ears of the AGV, amassing information concerning the surroundings during which it’s working. Generally wanted sensors for navigation, detection of obstacles, and security options in an AGV embody:

- Cameras: For vision-based navigation and object detection.

- Laser scanners: For correct distance measurement, mapping, and impediment detection.

- Ultrasonic sensors: For detecting shut obstacles, particularly when transferring in very restricted areas.

- Encoders: Measure the rotations of wheels to calculate the place and velocity of the AGV.

- Inertial Measurement Models (IMUs): Present data on the orientation and acceleration of the AGV.

- RFID readers: Used to acknowledge tagged objects or areas inside the warehouse.

These sensors work collectively to create a complete understanding of the AGV’s surroundings and, in flip, accomplish security and environment friendly navigation.

Actuators

Actuators are the parts that permit the AGV to maneuver and work together with its surroundings. They rework the controller’s instructions into bodily actions.

Listed below are among the key actuators:

- Drive motor: It powers the AGV’s wheels or tracks for motion.

- Steering mechanisms: AGV steering parts management the route and maneuverability.

- Carry mechanisms: Generally utilized in pallet vans and forklift AGVs to lift and decrease palletized masses.

- Brakes: Braking programs present stopping energy and maintain the AGV in place when stationary.

Energy System

The ability system supplies the vitality wanted for the AGV to function. It sometimes consists of:

- Batteries: Most AGVs use rechargeable batteries, usually lithium-ion for his or her excessive vitality density and lengthy life.

- Battery administration system: A BMS displays battery well being and controls charging.

- Charging interface: It permits the AGV to hook up with charging stations.

- Energy distribution system: It helps ship acceptable energy to all parts of the AGV.

Some superior AGVs function computerized battery swapping or alternative charging programs that permit prolonged operation instances.

Position of Machine Imaginative and prescient in AGVs

Machine imaginative and prescient is a know-how that allows machines to obtain and course of visible data as people do. This seems to be one of many key options, particularly for AGVs, for the programs to maneuver round and detect objects. The important thing parts for machine imaginative and prescient in AGVs are cameras, picture sensors, and software program algorithms for processing visible information. These programs permit the AGVs to “see” round them, thus facilitating real-time decision-making.

An instance is an AGV fitted with machine imaginative and prescient that can allow it to identify obstacles on its manner and therefore change the route for security and effectivity in performing its duties. The only most necessary profit of getting machine imaginative and prescient on an AGV is improved navigation accuracy. Conventional AGVs navigate in line with fastened paths or markers positioned in sure areas. This may very well be very limiting in dynamic environments with routes that is perhaps altering relatively regularly.

Machine imaginative and prescient allows AGVs to be extra versatile of their path planning by recognizing visible cues within the surroundings, comparable to traces on the ground or sure landmarks within the warehouse. The thing detection and recognition capabilities of the AGV are additional enhanced by means of machine imaginative and prescient. That is very helpful in environments the place the AGVs are to work together with different objects by selecting up some objects or avoiding obstacles. Machine imaginative and prescient programs might be programmed to acknowledge particular shapes, sizes, or colours, enabling AGVs to carry out duties with a lot enhanced precision.

Advantages of AGVs

The mixing of AGVs in warehousing supplies a number of advantages, therefore enhancing effectivity, productiveness, and security.

Effectivity

AGVs enhance warehousing efficiencies to a fantastic extent by means of the automation of fabric dealing with that’s in any other case carried out by means of human labor. Which means that with AGVs, items might be transported, pallets might be loaded and offloaded, and completed merchandise might be translocated from one storage space to a different with none interruptions for a break or attributable to shift adjustments. This ensures sooner processing with no bottleneck within the workflow.

Moreover, AGVs are so dependable and supply constant efficiency such that the work is all the time carried out accurately. Such consistency removes the randomness of human labor, and operations will probably be extra predictable and maintainable.

Productiveness

By automating repetitive and laborious jobs, the AGV releases human staff to interact in additional invaluable actions comparable to high quality management, stock administration, and customer support. This will increase the general productiveness of the employees and helps a enterprise get extra out of its workforce. On this regard, AGVs may very well be thought to carry out a form of 24/7 operation, rising productiveness.

In contrast to people, these autos don’t want relaxation intervals and will not be topic to fatigue, which means they’ll proceed working with out interruption. In industries the place demand is excessive, or there’s a very tight deadline in place, this type of steady operation is especially useful attributable to its fixed circulation of completed items.

Security

Security is essential in any type of warehousing, and using AGVs makes the working surroundings safer. They help in reducing the danger of office accidents relating to actions, which contain lifting heavy objects, extreme actions, or publicity to bodily risks. For instance, AGVs as forklifts eradicate such incidents as collision and tipping when manually working a forklift.

Additional, AGVs are geared up with higher-level sensors and security measures that allow the AGVs to sense and counter any barrier to motion together with pedestrians. It will reduce the dangers of potential crashes to create potentialities for AGVs to perform in the identical space as people.

Actual-world Functions

Automated guided autos are utilized in several industries; nevertheless, warehousing and manufacturing industries have benefited probably the most from it. Let’s discover some real-world functions and particular examples of AGVs in motion:

E-commerce Achievement Facilities

Amazon: The e-commerce big makes use of a fleet of AGVs referred to as “Amazon Robots” in its success facilities. These robots, acquired by means of the acquisition of Kiva Programs (now Amazon Robotics), transfer complete shelving models to human pickers, considerably decreasing strolling time and rising selecting effectivity.

Automotive Manufacturing

BMW: At its Spartanburg plant in South Carolina, BMW makes use of laser-guided AGVs to move automotive our bodies between manufacturing stations. These AGVs can carry masses as much as 2,000 kg and navigate with precision in tight areas.

Toyota: The automaker employs AGVs in its meeting crops for just-in-time elements supply. These autos use magnetic tape steering and RFID know-how to make sure correct and well timed supply of parts to the meeting line.

Meals and Beverage Trade

Nestlé: In its Biessenhofen warehouse operations, Nestlé makes use of AGVs for pallet transport and storage. These autos are built-in with AVG navigation with 360° laser scanners. This has allowed the plant to streamline its circulation of products in addition to cut back the quantity of inventory on its machines.

Future Traits of Automated Guided Autos

The sphere of AGVs is quickly evolving, with a number of rising applied sciences poised to form its future:

Synthetic Intelligence and Machine Studying

AI and ML algorithms will improve the intelligence and adaptability of AGVs. These applied sciences will permit the AGVs to study from their earlier operations, optimize their routes in actual time, and even resolve on complicated duties. Future AGVs will be capable of predict visitors patterns, anticipate obstacles, and even forecast upkeep wants.

5G Connectivity

The precise deployment of the 5G community will radically rework AGV communications. The excessive velocity and enormous quantity of end-to-end connections will facilitate real-time synchronization of a number of AGVs and central management programs. This improved connectivity will facilitate extra complicated and dynamic warehouse operations.

Superior Sensors and Laptop Imaginative and prescient

Future developments in sensors – LiDAR and 3D cameras will enhance the AGV’s notion talents. Advances made within the area of laptop imaginative and prescient will let AGVs grasp their environment in a fair higher manner, enabling extra exact navigation and manipulation of objects.

Swarm Intelligence

Swarm intelligence is impressed by nature and is an idea by means of which massive teams of easy AGVs may successfully remedy varied complicated issues. This might probably end in extra strong, and fewer brittle, types of warehouse automation.

By the implementation of those machine imaginative and prescient and different rising applied sciences, AGVs are gaining capabilities to adapt to probably the most difficult surroundings. With companies adopting and implementing AGV know-how, way more enhanced innovations on AGVs are anticipated over the approaching years making AGVs a robust basis of automated warehousing programs.

Incessantly Requested Questions (FAQs)

Q1. How do AGVs interface with Warehouse Administration Programs (WMS) and Manufacturing Execution Programs (MES)?

A. AGVs talk with WMS and MES through communication protocols that permit information trade and coordination of duties. This interface helps AGV process issuing, updates standing studies, and adjustments in manufacturing line or storage necessities. The AGV management system interacts with the WMS or MES for optimum project of duties, stock monitoring, and environment friendly help of fabric flows.

Q2. How is the navigation and impediment detection of AGVs enhanced with machine imaginative and prescient?

A. Machine imaginative and prescient permits AGVs to seize and course of real-time visible data from the surroundings. On this method, they’ll precisely detect obstacles, decide paths, and make navigation selections with superior algorithms of picture processing and sample recognition that permit them to distinguish between static and dynamic objects for collision avoidance and dealing with complicated environments whereas transferring.

Q3. What are the most important parts within the machine imaginative and prescient system of the AGVs, and the way do they work?

A. Cameras in AGVs are a part of machine imaginative and prescient programs that embody two or three dimensions, picture processors, illumination programs, and software program algorithms for picture evaluation. The cameras take information related to the view, and that is processed with picture processors in order to attract out among the necessary options. The picture evaluation software program algorithms acknowledge patterns, objects, and obstacles from these options for precise navigation and decision-making.

This fall. How is machine vision-based AGV localization completely different from conventional AGV localization strategies?

A. The traditional method to localization in AGVs bases itself on fastened infrastructures, comparable to magnetic tapes, RFID tags, or laser steering programs. In distinction, machine vision-based AGV localization makes use of environmental visible data to find out the place of the car regarding identified landmarks or objects. The methodology turns into liberal and dynamic in navigation since no further bodily infrastructure is required, subsequently enabling AGVs for use in numerous and altering environments.

Q5. How do AGVs contribute to lean manufacturing practices?

A. AGVs help lean manufacturing by means of improved materials flows, lowered lead instances, and minimized waste. They permit materials to be delivered simply in time, cut back guide dealing with errors, and contribute to area utilization. The automating function of repetitive work by AGVs helps in releasing human assets for extra value-adding actions and total lean initiatives.

Really useful Reads for Automated Guided Autos

Try the next article to study extra: